Hydraulic Grabs Maintenance

‘In service’ hydraulic grabs are working to a high duty cycle, therefore regular maintenance and overhauls can maximise the return on this equipment. At Hydraulic and Engineering, we have extensive knowledge and experience dealing with major overhauls on this type of product.

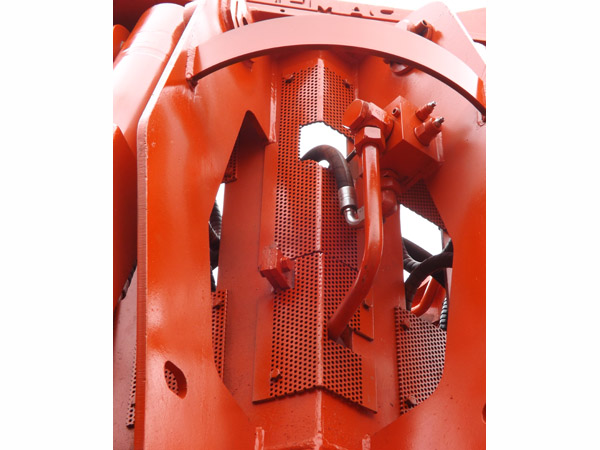

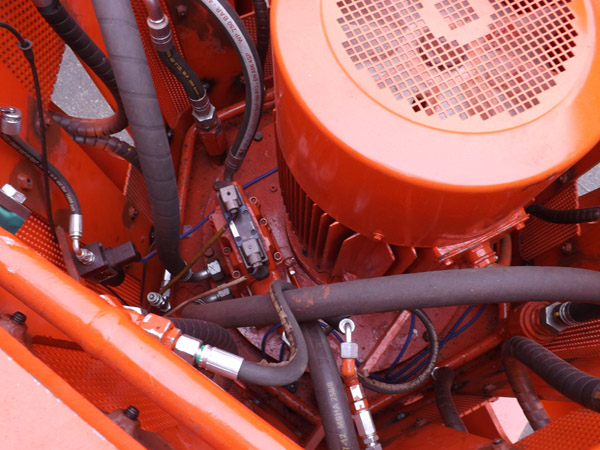

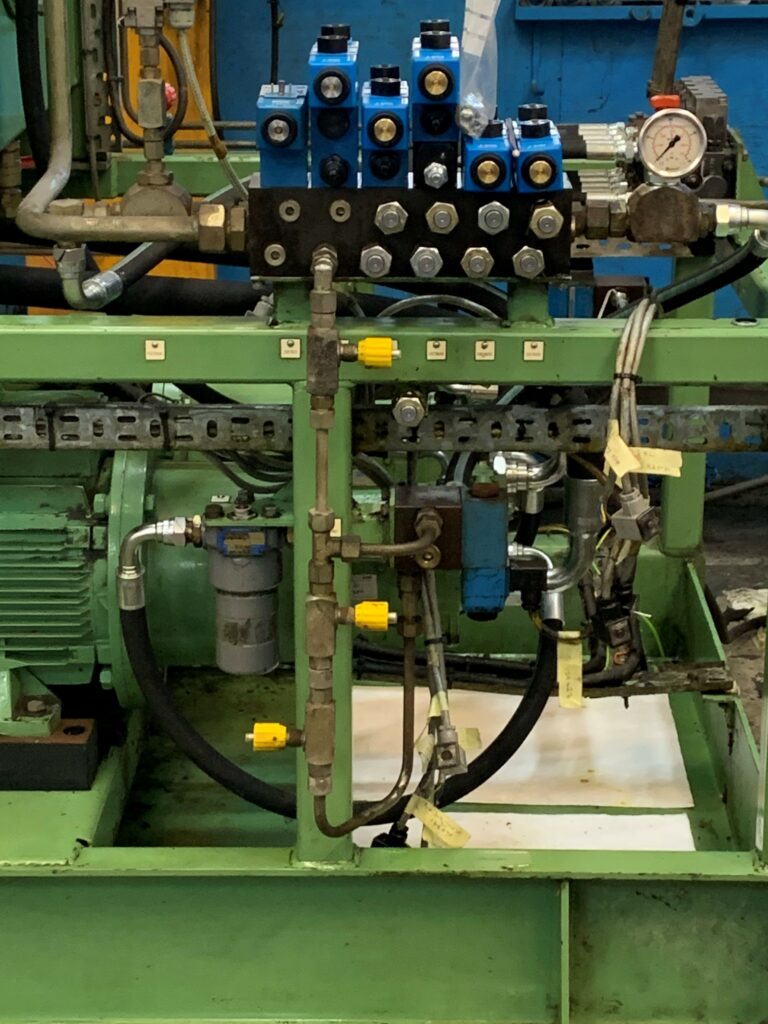

As the images show, in this case, after thorough cleaning, the complete unit is stripped to its component parts. Pins and bushes are replaced, the hydraulic pump is serviced and tested together with the electric motor. The complete hydraulic stack is tested . The distributor rings are pressure tested and the hoses replaced.

The wear on the tines is recovered and using Hardox plate and replacement tips. All of the welds on the body and tines are crack tested and ground out and re-run where necessary.

All bores are checked and out of tolerance holes are re-bored and recovered. The cylinders are completely refurbished and tested.

As each section is tested where necessary before the grab is assembled, when the complete grab is assembled it is fully tested on a stand ready for witness testing and sign off by the client.

There are many different types of grab and different levels of service that we can offer. Contact us with your requirements.