Hydraulic Cylinders, Pistons & Rams

Do you need Hydraulic Cylinders?

For all your hydraulic needs, we’ve got you covered

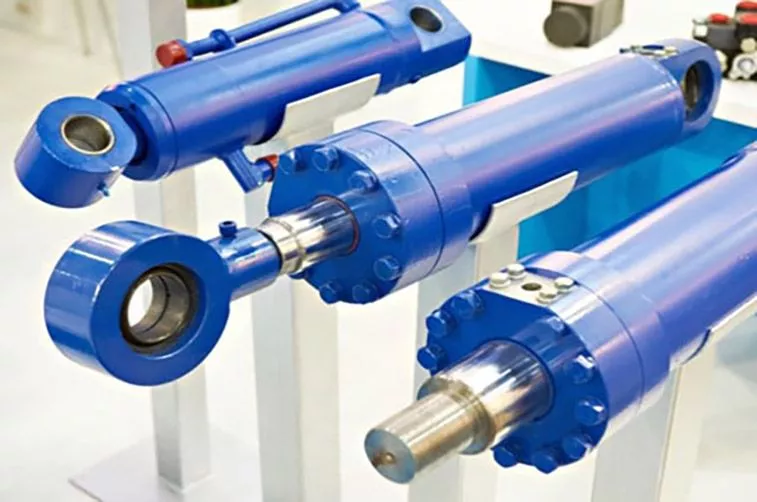

Hydraulic Cylinders, Pistons & Rams

Do you need

Hydraulic Cylinders?

For all your hydraulic needs, we’ve got you covered

Trust the Experts

Hydraulic Cylinder Design & Build

At HESL we have a wide range of capabilities to design and produce hydraulic or pneumatic cylinders. Manufacturing anything from tie bars for construction projects up to 4 tonnes in weight with lengths over 30 feet long! Our capacity includes single-acting units as well so your request will be met quickly even if it requires us to do something special on order just for you. We also offer custom-made products based on customers’ own specifications.

Hydraulic Cylinder Manufacture

Hydraulic engineering is at the core of everything we do. Our machine shop has a combination of manual and CNC machines, which allows us the flexibility to produce batch runs of cylinders and components or one off specials competitively.

Hydraulic Cylinder Repair Service

If you are experiencing recurring faults or failures – our design team can evaluate your application and where necessary re-engineer your cylinders to remove the problems.

Our hydraulic repair services site service division is available to cover a wide range of disciplines including diagnostic work, new installations, removal and re-installations of components, upgrades, renewals, hose replacement service, and system monitoring including trend analysis.

Applications

Contact the team today to discuss your specific requirements.

Excavator Attachments

Waste & Recycling

Agriculture

Aerial Work Platforms

Material

Processing

Commercial Vehicles

Aviation Ground Support

Bespoke

Why use Hydraulic & Engineering Services

Committed to the manufacturing and supply of high-quality hydraulic cylinders, hydraulic repairs, and hydraulic equipment to the industrial, mobile, and marine markets. We work to multiple accredited standards such as Achilles and ISO 9001:2015. Hydraulic and Engineering Service Ltd are leading the way in hydraulic engineering.

From new projects and installations to updating old and redundant equipment, our design team can help! We have a long history of cylinder design. We have engineered out failures to existing equipment as well as designing new cylinders for new applications.

Operating across many sectors, the variation of type, material, duty cycles, and pressures/ speed capabilities of bespoke cylinders we have designed also significantly varies. From standard agricultural-type cylinders to multi-stage double acting in stainless steel.

Highly Trained Staff

Multi skilled workshop team delivering a high standard every time.

Quality Workmanship

Our expert engineers provide quality workmanship consistently.

Many Years Experience

HESL LTD have been established for over 30 years.

Bespoke Products

Custom design, build and install of hydraulic cylinders & systems.

ISO Accreditations

Trust in our systems & processes.

Some of our work

Hydraulic Solutions for all types of business & organisation

If you have a question or specific requirements please get in touch, our team are ready to assist.

Hydraulic & Engineering Services Reviews

What our customers have said

Hydraulic Cylinder FAQ

A hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment, marine hydraulics, (engineering vehicles), manufacturing machinery, and civil engineering.

Hydraulic cylinders get their power from pressurized hydraulic fluid, which is typically oil. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. The barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called the gland) where the piston rod comes out of the cylinder. The piston has sliding rings and seals. The piston divides the inside of the cylinder into two chambers, the bottom chamber (cap end) and the piston rod side chamber (rod end / head end).

Flanges, trunnions, clevises, and lugs are common cylinder mounting options. The piston rod also has mounting attachments to connect the cylinder to the object or machine component that it is pushing or pulling.

Quick Links

Latest Blogs

2022 Hydraulic & Engineering Services Ltd. All right reserved.